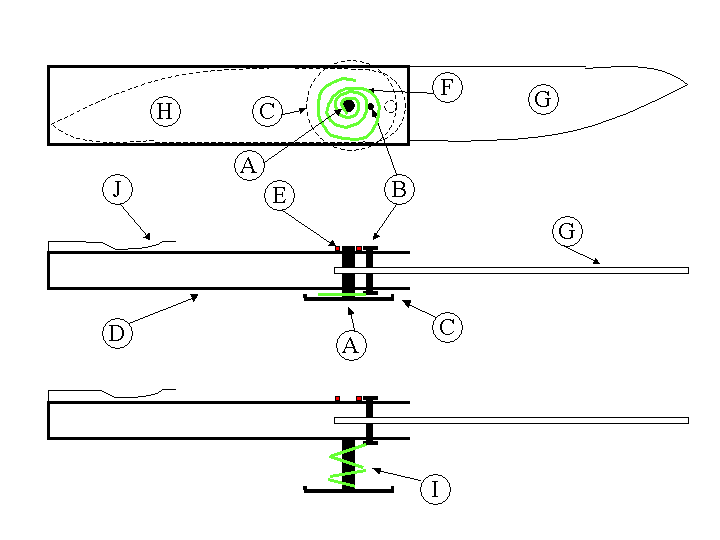

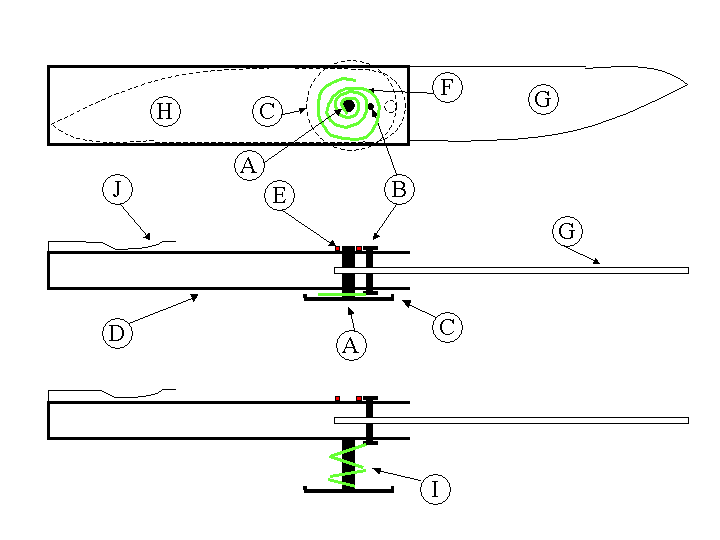

Fig. 1.

Let's Adore Jesus-Eucharist! | Home >> Varia >> Bachelor's Kit

As explained in the "Jackknife" Section of my EDC, I can't find the jackknife I want on the market. Here is my best attempt at describing My Dream Jackknife.

The design space has already been fairly-well explored here. Here's an attempt at walking down the design-space tree, starting with the biggest branches:

2.1) Folder or fixed-blade? Folder. A folder (that somehow had a folding mechanism that could make it as strong as a fixed-blade) can do everything a fixed blade can do, not the other way around.

2.2) Knife or Jackknife? Jackknife (i.e. many tools on one object). The current practical solution requires three objects, including one jackknife. So if one object is to replace all three, it has to have many tools in one object.

2.3) Folding mechanism? All of the folding mechanisms I've read about on the Internet seem to have empirical failure events resulting in cut fingers, as well as theoretical failure modes (e.g. if you grip it in such a way, or twist the handle in such a way, the locking mechanism will fail). The only folding mechanism I would trust is the simplest: one pivot bolt, and one screwable locking bolt. See description below. It's basically the same mechanism used to connect the handle to fixed-blade knives, but with bolts instead of rivets.

2.4) Size? The biggest I'd be able to tolerate in my pocket on a daily basis would be the size of the Victorinox Outrider.

2.5) Which tools? One of the advantages of having a custom-made jackknive with big nuts and bolts holding the tools is that you can easily change the tools yourself. So as long as the tool respects a few modularity constraints, you can mix-and-match whatever tools you want. Another advantage is that you can easily replace broken tools.

Here are, as far as I can in decreasing order of importance, the tools I'd put on this jackknife. I think they could all be made to fit in the target handle size:

2.5.1) Big blade (self-defense). For self-defense, a bit of gentle prying, a bit of wood cutting. Maybe when folded a bit of it's pointed back could stick out, to allow breaking a tempered glass window after a car accident. Shape, size and grind like AlMar SERE 2000. Carbon steel (to keep a good edge).

2.5.2) Small blade (kitchen). Like the thin and flexible Victorinox kitchen knife I use daily. Blade of stainless steel.

2.5.3) Scissors. Scissors don't look sexy or tactical, but I use the buggers quite often. If I could get the Victorinox Climber scissors, but 33% bigger, I'd be happy. I could do my toenails and fingernails, and in a pinch use them as EMT shears.

2.5.4) Awl. A long pointy object is surprisingly useful. (Another useful object is some large, flat object used for prying. That type of operation is sort of taken care of by the big blade). If on top of that you can put a hole toward the tip, and a "gutter" along it's length, you can add all the advantages of a sewing awl. (Very useful for fixing many pieces of outdoor equipment that cannot be sewn with a normal needle.) If you look at a normal sewing awl, it's filled with redundant parts: you don't need a spool for the thread (when you sew with an awl, you start with a short length of thick waxed thread, and just let it hang while sewing), you don't need a handle (that is provided by the jackknife), and you don't need some big and heavy mechanism to screw and unscrew the needle (the needle is already held by the two bolts of the jackknife). So you add some useful features with very little added weight or complexity.

2.5.5) Sewing needle. Small and useful. Easy to find some place to keep it in such a large jackknife. On my Victorinox Climber, I just hold a sewing needle in the tweezers, and slide the tweezers into their compartment.

2.5.6) Tweezers. They don't take up much place, and it's really nice to be able to pull out wood or metal splinters out of your hands. They would be about the same size, but of much better quality (more pointy) than the standard tweezers on a Victorinox Climber.

2.5.7) Metal saw. Yes, a wood saw is nice, and they are handy to cut branches, and there are some gorgeous wood saws out there (e.g. Silky Gomboy). But when push comes to shove, a metal saw can cut wood (very slowly and annoyingly), but a wood saw can't cut metal (and neither can a knife blade, big or small). Cuts on pull stroke. Ideally, larger teeth on one edge, much smaller teeth on the other. Very small metal saw teeth are almost smooth to the touch, so it wouldn't matter if the palm of the hand made a bit of contact with them when gripping the handle. These very small teeth would be used to cut wire (far inferior to diagonal cutters, but much better than nothing). Metal saw blades tend to break and wear out often, but this jackknife design allows easy replacement of blades.

2.5.8) Can opener. The standard Victorinox Climber can opener is small and works fine. It also doubles as a small flat screwdriver (which I end up using to screw small Phillips screws in a pinch).

2.6) Handle material? The basic shape of the handle would be given by the tool compartment made of metal. So some kind of slip-on moulded synthetic grip (held by the main pivot) would provide a non-slip surface even with sweaty hands, would allow the addition of lightweight and small "ergonomic bumps" to prevent the hand from slipping forward (onto the knife) or backward (off the handle) or slipping rotationally (handle twisting inside the gripping hand), and would have no sharp corners to provide a comfortable grip and avoid damaging pockets.

2.7) Pocket clip? Yes, as AlMar SERE 2000, unfortunately probably only tip-up carry.

Fig. 1.

Legend:

A) Screw bolt. This is the bolt that is pulled out to allow blades and tools to be folded in or folded out.

B) Pivot bolt. This is a plain nut and bolt upon which all tools pivot. It is never removed except to change a broken tool, etc.

C) Thumbwheel. Actually the head of "A" (it's the same piece of metal). Diameter just large enough to be wider than body of jackknife, so that it's easy to grab and pull out, also large diameter to provide more torque. Edges are knurled to allow easy grip, so it can be tightened and unscrewed even with sweaty fingers.

D) Frame. Basically a large "U"-shaped piece of steel.

E) Screw bolt nut (red). I guess an ordinary nut, but welded to the side of "D". This is what gives me confidence that the blade cannot fold back on my fingers; once part "A" is tightly screwed into this, the blade might break, but it won't snap back on my fingers.

F) Thumbwheel spring (green). I don't know if this would work, but maybe a spring, attached at one end to "A" just underneath "C" (maybe with a fancy spring shape, it could be almost like a "circlip", so it would snap into a groove of "A", so it would retain "A" while allowing it to turn easily), and at the other end to "F".

G) Big blade (unfolded position).

G) Big blade (folded position).

I) Screw bolt. Extended position, to allow movement of blade.

J) Belt clip.

Let's Adore Jesus-Eucharist! | Home >> Varia >> Bachelor's Kit